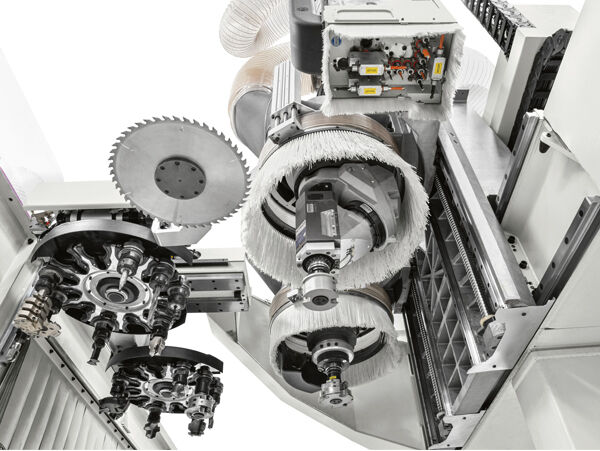

accord 600 represents the best design solution for machining doors, windows, stairs and solid wood elements. In order to fully reduce production times, the machining center is equipped with a hyper-performing operating group with 3 independent units.

HIGH PRODUCTIVITY

Tool changes in hidden time:

the operator group features two independent units, with 4- and 5-axis JQX electrospindles, each equipped with its own on-board tool changer.

UTMOST VERSATILITY

Extremely reduced production cycle times thanks to the exclusive BRC-S unit, even more flexible and compact, that allows to perform all the cutting, routing and drilling operations typical of window components.

FLEXIBILITY AND INNOVATION

Up to 102 tools always available on board with the new integrated CADDY 35 tool changer: it plays the dual role of tool changer and «warehouse» serving the other on-board tool changers.

Technical data

| accord 600 | ||||

| Working areas | ||||

| X-Y-Z axes dimensions | mm | 3715 x 1600 x 300 5515 x 1600 x 300 6715 x 1600 x 300 |

||

| Axes | ||||

| X-Y-Z axes max. speed | m/min | 90-80-45 | ||

| Routing unit | ||||

| 5 axes electrospindle motor power (max.) | kW (hp) | 13,5 (18,4) | ||

| 3/4 axes electrospindle motor power (max.) | kW (hp) | 21 (28,5) | ||

| 5 axes electrospindle rotation speed (max.) | rpm | 24000 | ||

| 3/4 axes electrospindle rotation speed (max.) | rpm | 24000 | ||

| Tool changers | ||||

| TRB side tool changer | positions | 11 | ||

| CADDY side tool changer | positions | 35 | ||

| RAPID rear tool changer | positions | 16 | ||

| TRC rear tool changer | positions | 32 | ||

| VELOCE on-board tool changer | positions | 12+12 | ||

| Drilling unit | ||||

| Vertical and horizontal spindles (up to) | n. | 26 | ||

| Rotation speed (max.) | rpm | 8000 | ||

| Integrated saw blade | Ø | 125 | ||

CONSENTIMIENTO PARA EL TRATAMIENTO DE DATOS PERSONALES

Responsable del tratamiento: JURADO MOYA S.L.

Fin del tratamiento: Tramitar encargos, solicitudes o cualquier tipo de petición que sea realizada por el usuario a través de cualquiera de las formas de contacto que se ponen a su disposición.

Base jurídica en la que se basa el tratamiento: Por interés legítimo del responsable, Por consentimiento del interesado

Criterios de conservación de los datos: se conservarán mientras exista un interés mutuo

Comunicación de los datos: No se comunicarán los datos a terceros, salvo obligación legal.

Derechos que asisten al Usuario: Derecho a retirar el consentimiento en cualquier momento, Derecho de acceso, rectificación, portabilidad y supresión de sus datos y a la limitación u oposición al su tratamiento,Derecho a presentar una reclamación ante la Autoridad de control (www.aepd.es) si considera que el tratamiento no se ajusta a la normativa vigente.

Información adicional: puede consultar la información adicional y detallada sobre Protección de Datos en: «pagina de politica de privacidad de la empresa»

Háblanos por Whatsapp